If you’re in the field of many industries that require continuous production and work so that everyone does their work on time, you know the importance of transmission. Transmission, in technical terms, is the controlled application of power and you use it in packaging, material handling, conveyor belts, and many other applications. Transmission, or rather, its parts, ar used in machine tools, industrial equipment, conveyors and rotary motion power transmission where torque and speed are needed. Yet, despite their widespread use and function, they mainly consist of two simple parts that work together.

Those two parts are the gearbox and the motor, which are small enough to move them by hand, but they do all the main work, and both play a specific role in transmission units. However, things can be slightly more complicated from this point on. There are many types and many brands. As such, the goal of this article is to provide an intro into the Motovario brand. Specifically, what products they offer and what makes them so good, versatile, and reliable.

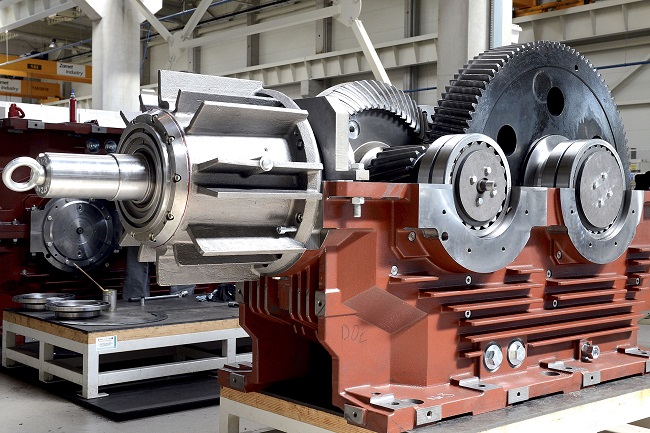

Gearboxes

What this part consists of is self-explanatory as the name gives it away. It’s a box of gears. An exact technical definition is a mechanical unit or component with a housing that consists of a series of integrated gears. Function-wise, to give a technical description, they are speed reduction parts used in automation control systems.

They do this by reducing the speed of a prime motor output shaft while simultaneously lowering the torque. Due to this, they’re also popularly called reducers. Or, you can use them vice versa to reduce the speed and increase the torque.

Gearboxes are beneficial as they improve the operational output regarding the creation of products. They cut down on operation time, so the work is done quicker and more efficiently. This is done in three ways – torque manipulation, speed reduction and inertia matching. Additionally, they cut down on the needed maintenance as you can easily repair them and control their work at all times. Accordingly, they can also save costs and expenses. That said, Motovario distribution stands out due to the range of gearboxes it offers with its technical prowess. All of them are specialised for use in specific fields.

Worm Gear Reducers

You use this type of gearbox for heavy-duty operations, such as when dealing with minerals and chemicals. The reason for this is that they allow you to increase speed when they’re between non-intersecting crossed axis shifts. Furthermore, they feature a worm wheel with a large diameter for this purpose. As the worm engages with the teeth of the gearbox’s peripheral area, its rotating motion impacts the wheel to move similarly due to its movements, which resemble a screw. Opposite of them are planetary gearboxes, which lower the speed but increase the torque.

Helical Gearbox

This one is compact and consumes little power, but you can use it for a broad range of industrial applications, and it’s widely used in construction. You’ll find them in the construction of plastics, cement, and rubber, but also in coolers, conveyors, crushers and similar. The reason why it’s so powerful and allows for this is that it has one unique feature. It is fitted at an angle that enables more teeth to interact in the same direction, which provides constant contact for some time.

If you want to get a Motovario Helical gearbox, you’ll have to decide on the material. They have two types, iron and aluminium, or the H and HA series, as they call them. Both function with different machines, but the difference between the materials is resistance. Aluminium is better against corrosion and natural elements as it doesn’t rust and can bear them. On the other hand, iron is durable in many industrial applications but is weak against rain or acid.

Helical Bevel Gearbox

If you work in quarries, the mining industry, or with conveyor belts, this is the one for you. They have a curved set of teeth at the cone-shaped surface at the rim of the unit. They can perform rotary motions between non-parallel shafts.

Shaft-Mounted Gear Reducer

Unlike the previous ones, the shaft-mounted Motovario Australia is substantially different. The reason why is explained by the name, you mount it on the shaft, and it doesn’t require a foundation on its own. It’s super practical, however, as it eliminates a lot of other components. You can save up on space on several flexible couplings and external belt arrangements. It’s also convenient to use as it quickly and efficiently reduces the speed.

Motovario Disco

Last is the disco gearbox, which lets you control the speed from 0 RPM to maximum, depending on the motor’s capacities. You use them with epicyclic differential units.

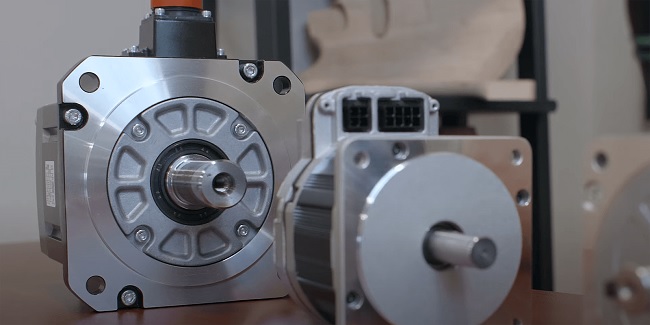

Motors

In the simplest terms, motors convert energy, whether electric, pneumatic or hydraulic, into motion. A classic example of this are servo motors, which are not of interest to us. The energy they make is of a rotational or linear motion which is outputted to a shaft or another power transmission component. Motovorio distributors only have one, which is the AC motor. The AC motor is an electrical one that functions on alternating current.

Despite the offer of only one motor, it truly shines and has many great characteristics. The first one is regarding phases. Their motor can function both as single-phase or three-phase one. This duality leads to one crucial advantage to their functioning. If you use the single-phase, you’re producing an alternating magnetic field, while with the three-phase, you’re producing a rotating one. Furthermore, the single-phase need a starting mechanism, unlike the three-phase, which start by themselves.

This mix of both phases is cost-efficient as it saves you money in both the upkeep of it and the uses. The single-phase is cheaper and easy to repair, and the three-phase is the opposite of that. This one lets you have the best of both worlds. Finally, you can use single-phase for lighter loads, like a grinder, compressor, centrifugal pump and similar. On the other hand, you use the three-phased ones in industrial and commercial drives since they can output more and provide more operational efficiency.