One essential tool that is heavily used in the mining industry is the powerful ball mill. People also call it a grinder. That’s because the main purpose of the ball mill is to grind and reduce the size of different materials. Even though the ball mills are most commonly used in the mining industry, these machines can be found in other industry sectors as well, like metallurgy, chemistry, ceramics and construction. This tool is described as highly efficient and versatile, as it can mix, blend, grind, and crush massive materials into fine powder.

The first ball mill was introduced 20 years ago in Germany. Before the ball mill, people used similar grinding mechanism to reduce the size of the materials that were needed for further use. A ball mill can grind raw materials in two ways: dry or wet grinding. It’s important to mention that two types of ball mills stand out on the market. That’s the grate type and the overfall ball mill. This classification is made depending on how the materials are discharged through the mill.

Design

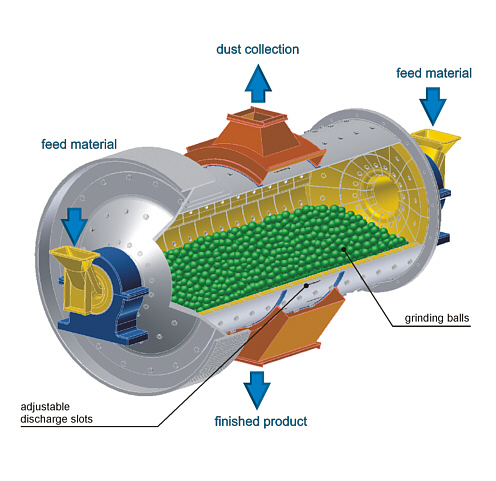

The design is pretty simple. A ball mill consists of a cylindrical shell that rotates around its own axis. Inside the shell, you will notice stainless steel or rubber balls, also known as media. The inner surface of the cylindrical shell is coated with material which is abrasion-resistant in order to protect the shell from the constant ball hitting. As there are different ball mills on the market, the design can vary. Each ball mill has different size and rotating ratio. It’s up to you to decide, which one fits your budget and job requirements.

Basic Principle

The working principle is not complex as well. The material that needs to be processed is placed in the cylindrical shell through the top opening. Once the material gets the desired size, it is discharged from the opening at the bottom. The minute you start the ball mill, both the shell and the balls inside start to rotate and to grind the material. It’s important to keep the ball mill running at a low operating speed. That speed is also known as critical speed. At that speed the balls inside rotate in the same direction as the cylindrical shell.